|

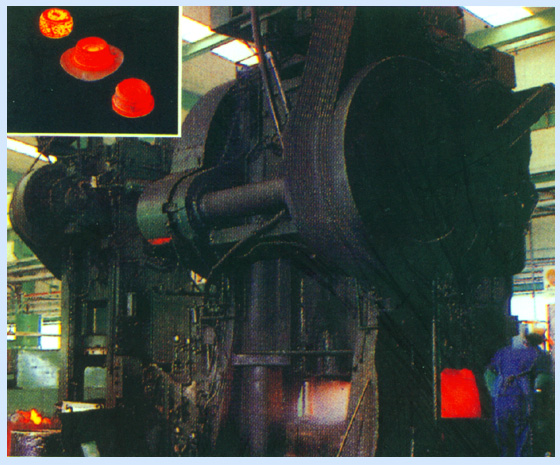

HOT

FORGING DIE RELEASE LUBRICANT

[TRANSPARENT TYPE]

DESCRIPTION

DESCRIPTION

BW-100

is a smokeless water-based graphite die release lubricant designed

to meet the forging industry's needs when W-200 is not suitable.

BW-100 is especially effective for difficult mechanical press work

and highly automated facilities requiring graphite lubricant. BW-100

forms a uniform dry film coating when sprayed on dies.

PROPERTIES

PROPERTIES

| Specific gravity |

: |

1.18 ~ 1.23 (15/4℃) |

| Viscosity |

: |

Powdered graphite products are difficult to

measure the precise viscosity. |

| Freezing point |

: |

-9℃ or -10℃ |

| |

: |

(-20℃ or -4°F for frigid zone) |

| Carrier |

: |

water |

| Appearance |

: |

black |

| pH |

: |

11.0 ~ 11.5 |

※

The above number can be changed according to product development

and other circumstances.

FEATURES

FEATURES

APPLICATION

APPLICATION

Demoulding lubricant for hot forging

of steel (especially more difficult work, precision forging),

stainless steel, nonferrous metal, and aluminum extrusions

USAGE

USAGE

-

Dilution : For initial trials, one part of BW-100 to ten parts of water by

volume is suggested. We recommend to determine dilution ratio during operation

according to the condition of die surface and the working condition.

-

Application : Spray (Manual

or automatic)

STORAGE

STORAGE

SHELF LIFE

SHELF LIFE

- 1 Years under the original seal

(※ The term of validity is not absolutely number, which can be extended)

WARM

FORGING LUBRICANT

It has the similar ingredient as hot forging type BW-100 and has a strong application effect.

Application

Application

Warm forging lubricant especially for synchronized shafting and gear forging

Usage

Usage

The material should be kept between 100℃±10 during deeping or spray

deeping. It should be diluted with water with the dilution ratio

of "water:BW-100(warm forging)=5:1." For spray, it should be diluted

with water with the dilution ratio of "water:BW-100(warm forging)=8:1."

※ This products may happen to have some sedimentation,

but it can be easily diluted with water and use with no problem

|