|

HOT

FORGING DIE RELEASE LUBRICANT

[TRANSPARENT TYPE]

DESCRIPTION

DESCRIPTION

Until

recently, graphite power, or a gel derived from graphite, has been

the most commonly used material in the manufacture of die release

lubricant for the hot forging.

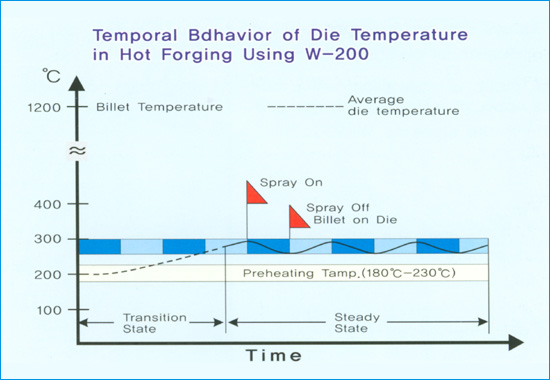

Since 1982, our company has developed a transparent, non-polluting,

liquid die release lubricant, W-200 that overcomes the environmental

disadvantages of graphite lubricant.

W-200 is highly appreciated by lots of users.

( NOTE : If it is mixed with purified water with the dilution ratio

of "water:product=60:1", goldfishes can live in the mixture

for a long time. But the Specific gravity, PH, Viscosity of water

can affect the results.)

PROPERTIES

PROPERTIES

| Viscosity |

: |

300 ± 20% |

| Specific gravity |

: |

1.10 ± 10% |

| pH |

|

9~11 ± 10% |

| Freezing point |

: |

-9.5 |

| Appearance |

: |

Transparant~Light yellow |

※

The above number can be changed according to product development

and other circumstances.

FEATURES

FEATURES

APPLICATION

APPLICATION

Die release lubricant for hot forging of steel,

stainless steel, non-ferrous metal, and aluminum extrusions

USAGE

USAGE

-

Dilution : The dilution ratio

depends on the workability of the job and the condition of the

die. Ratio of 1:8 ~ 10 (product:water) is suggested for first

trial; in some cases, it can be diluted with water than 20 times

-

Application : Spray (Manual

or automatic)

STORAGE

STORAGE

SHELF LIFE

SHELF LIFE

- one

year under the original seal

(※ The term of validity is not absolutely number, which can be extended)

Environmentally-friendly W-200 Series Products

Environmentally-friendly W-200 Series Products

This Products has no defect even when some additive lump is seen in appearance, can be used diluted with water, totally no problem.

|